Plano Optics

Depending on the application, Plano optics (also known as optical flats) may have one or both sides polished to a certain standard. When evaluating the flatness of optical windows, prisms, and other Plano optics, one-sided optical flats are commonly utilized as reference surfaces. However, double-sided optical flats can be used as optical windows and test plates due to their capacity for light transmission. Since different materials transmit light at various wavelengths, the application determines the material we use when building optical windows.

Salvo Technologies has the tools and know-how to produce Plano optics in both volume and size on a large scale. Our 72” planetaries allow for up to 30” parts and are better than 1/20th wave at 632.8nm. Our Speedfam double lap polishers produce parts with less than 5” parallelism. Both areas can manufacture thousands of optics over 8” per month. Scratch dig or 10/5 on visible optics and 20/10 on IR optics are possible.

Depending on the needs of your application, Salvo Technologies has decades of experience making Plano optics from various materials. As a result, we can produce Plano optics that fit your requirements, whether they require hard ceramics or soft optical materials.

Optical windows are often made from two flat, polished surfaces that are optically transparent and designed to segregate, seal, or otherwise protect other components. These surfaces are known as planos in the industry. The remarkable parallelism and transmitted wavefront produced by the double-sided production process make it perfect for visible windows in industrial and biomedical applications and IR windows in infrared and military/defense applications.

At Salvo Technologies, we have extensive experience fabricating and producing customized IR, UV, and visible windows in various sizes, shapes, and substrates servicing the medical, defense, industrial, and scientific fields. In addition, we are proud to own one of North America’s most extensive collections of double-sided grinding and polishing machines.

Make Optical Substrate Types & Window Shops two-column list. Place them next to each other.

Optical Substrate Types

- Crystal

- Display Glass

- Fused Quartz

- Fused Silica

- IR Materials

- Low Expansion

- Optical Glass

Window Shapes

- Circular Windows

- Square Windows

- Rectangular Windows

- Elliptical Windows

Visible windows are designed to be used with light visible to the human eye or in the visible spectrum. Visible windows are excellent for safeguarding image or display systems, including optical systems and other optical components. Salvo Technologies can custom-build visible windows in several sizes, shapes, and substrates with an option for AR coating on one or both surfaces for various optics applications with a wide range of temperatures or other complex environmental factors.

Infrared windows are commonly used in the infrared light spectrum for FLIR, FTIR spectroscopy, medical systems, thermal imaging, or other optical applications. In addition, IR windows can aid in securing your personnel and machinery. For several infrared applications, Salvo Technologies can custom-create IR windows in various sizes, shapes, substrates, and coatings with an option for AR coating on either or both surfaces.

In medicine, industry, and military fields, ultraviolet windows are frequently utilized in conjunction with laser equipment or other applications. To best meet your unique requirements and applications, Salvo Technologies can assist in identifying the optimum substrates, UV coatings, and other optical qualities and produce UV windows specifically for you with an optional AR on one or both surfaces.

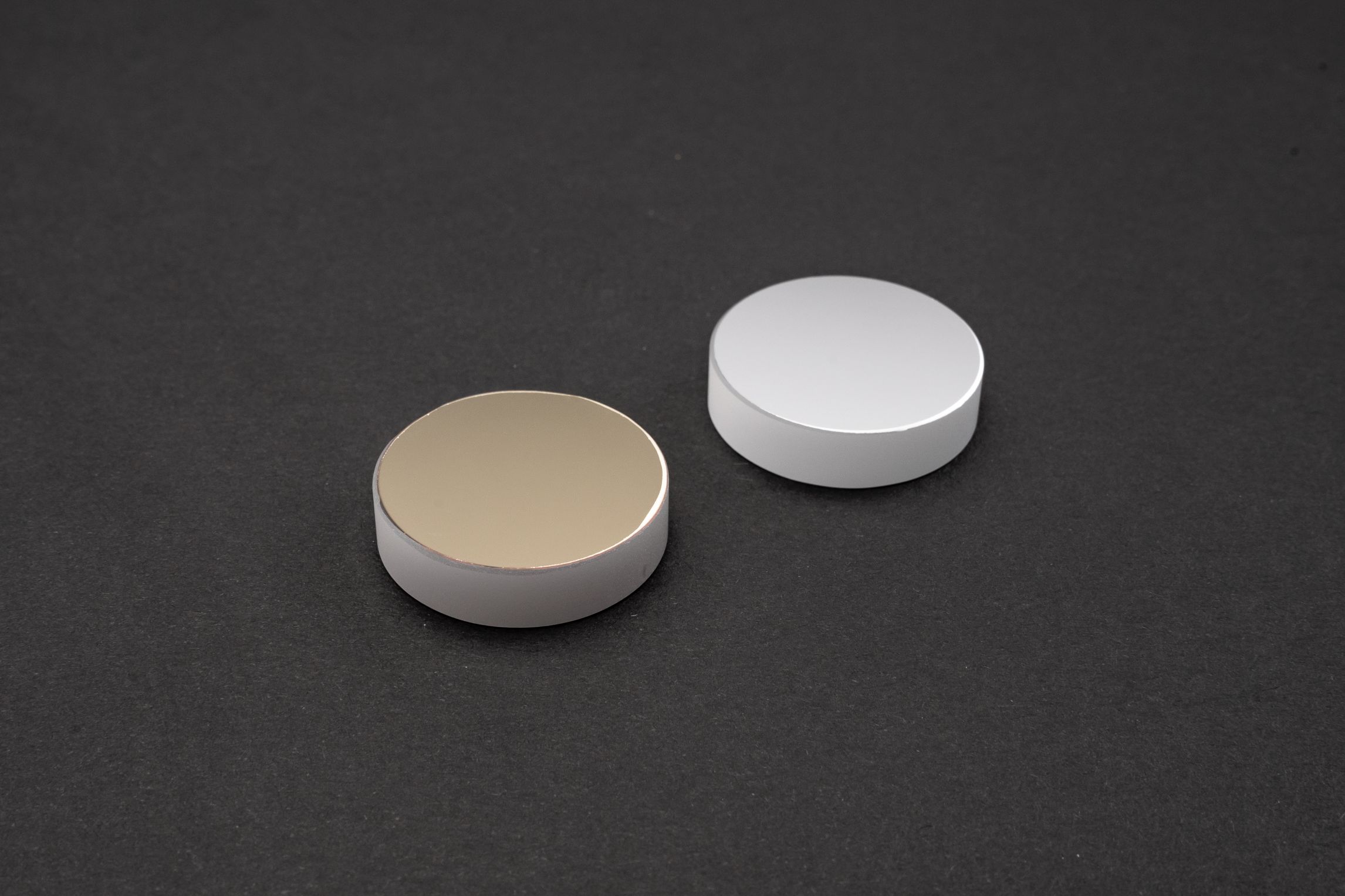

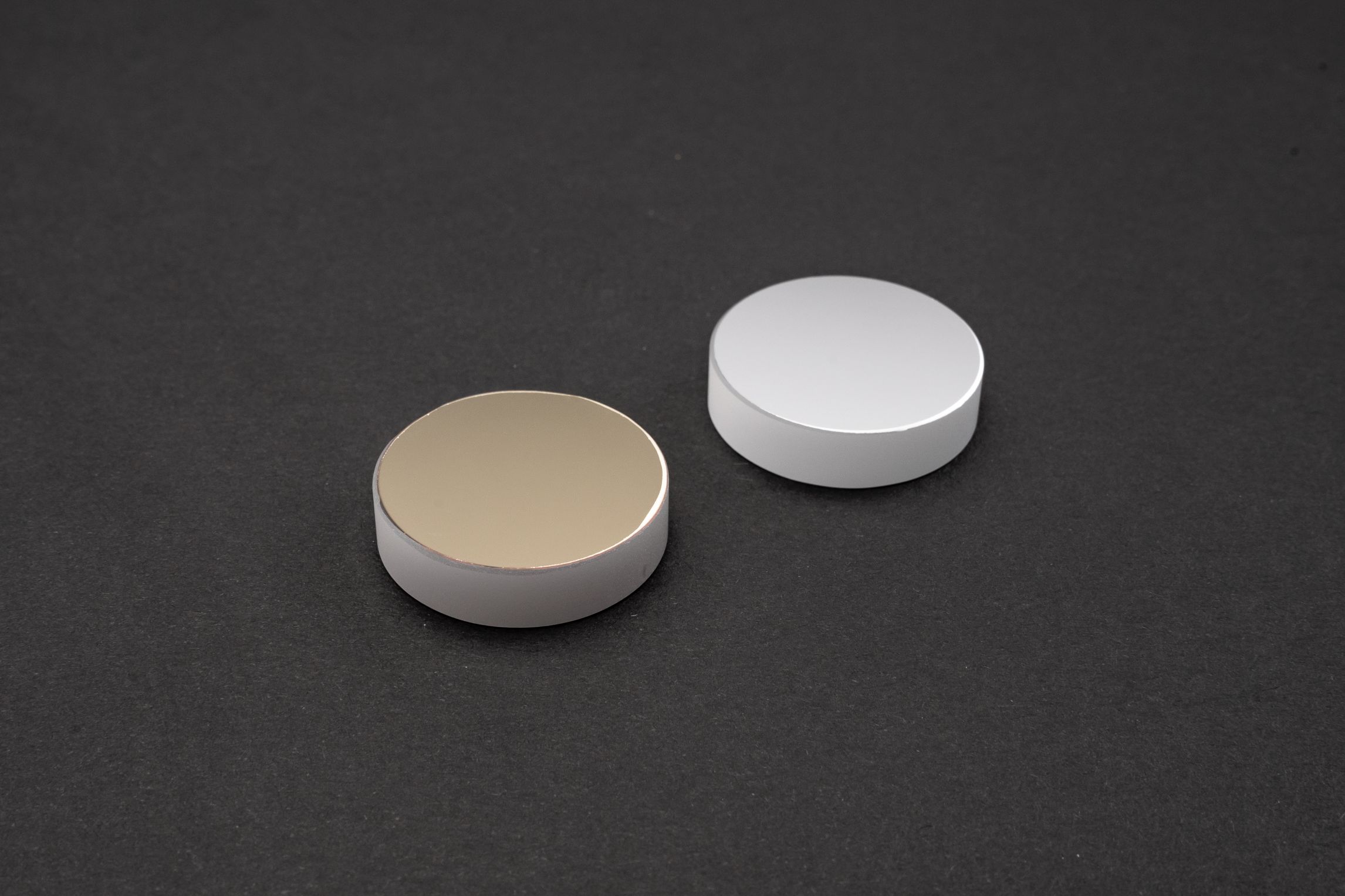

Salvo Technologies offers several optical flats, sometimes referred to as “reference flats,” “test flats,” or “test plates,” to fulfill precision tolerances for the most demanding and rigorous applications. For example, an optical flat, which is made to be incredibly flat, is a reference for evaluating the flatness of other optics using a monochromatic light source or in interferometry applications. Other flat optical components, such as optical windows or substrates for optical mirrors, are sometimes referred to as “optical flats” or “Plano optics.”

Optical flats are made to order in custom sizes with various coating and beveling options. They can even be polished to contain a small wedge to lessen back reflection. Salvo Technologies will satisfy your requirements for precision and accuracy whether you need single-sided or double-sided Plano optics that are λ/4, λ/10, or /20 in size.

It is essential to choose a reputable vendor when utilizing optical flats to assess the flatness accuracy of an unknown optical surface: Here at Salvo Technologies, we have decades of experience fabricating and resurfacing/refinishing optical flats.

Material Types

- Display Glass

- Fused Quartz

- Fused Silica

- Low Expansion

Flats with only one side of precise polishing are called single-sided optical flats. The opposing side is not polished to specifications but is left clear. Other optical materials, such as wedges or optical mirrors, can have their flatness tested using the polished side of the optical flat. It can also function as a substrate for optical windows.

Plano optics with a known flatness on both sides are called double-sided Plano flats. A double-sided optical flat can be used as a substrate for a window or to evaluate the flatness of an unknown surface on either side.