Optical Assemblies

Salvo Technologies transforms ideas into operational realities in the research, aerospace, and defense markets. We are committed to constant development to keep up with the rapidly advancing optical industry. We collaborate with engineers and physicists globally to offer a full spectrum of design and manufacturing services. From customer’s build-to-print drawings to conceptual design specifications to complete engineering services, we have the tools and resources needed to meet your requirements.

We work with various optical substrates, metering structure materials, and a wide range of optical glasses. We have extensive experience with different specialty optical and mechanical coatings.

Our fully equipped in-house machine shop includes (25) 4 and 5-axis Vertical Machining Centers, (11) Lathes, (6) with live tooling and sub spindles, (17) axis mill-turn, a 30mm Swiss lathe, and (3) Wire EDM’s.

To evaluate the accuracy of our assemblies, Salvo uses sub-micron measurement instruments such as interferometers, alignment stations, OGP, Nikon collimators, Nikon measure scope, Uniscopes, MTF testing, and Zeiss coordinate measurement machines.

We have the resources to build virtually anything your team can imagine, and our strong internal metrology capabilities can affirm this. Our in-house design and manufacturing capabilities enable us to provide high-quality complex optomechanical assemblies quickly and at a more affordable price.

Optical waveplates are transparent plates with a carefully selected level of specular reflection. Their primary function is to control the polarization condition of light beams.

Quartz (crystalline SiO2) is a common material for waveplates because it has a broad wavelength range, a high degree of transparency, and can be produced with excellent optical quality. Other such substances include mica (a silicate mineral), calcite (CaCO3), magnesium fluoride (MgF2), sapphire (Al2O3), and a few birefringent polymers. Numerous factors, such as wavelength range, open aperture, absorption losses, and high-power capability, can influence the material choice.

At Salvo, we manufacture waveplates in any configuration the customer requires. Our in-house waveplate fabrication and coating give us complete control from start to finish. We orient, cut, and polish the optical crystals for waveplate manufacturing at all wavelength ranges.

Our waveplates are utilized in cutting-edge research, high-power laser systems, and semiconductor metrology equipment.

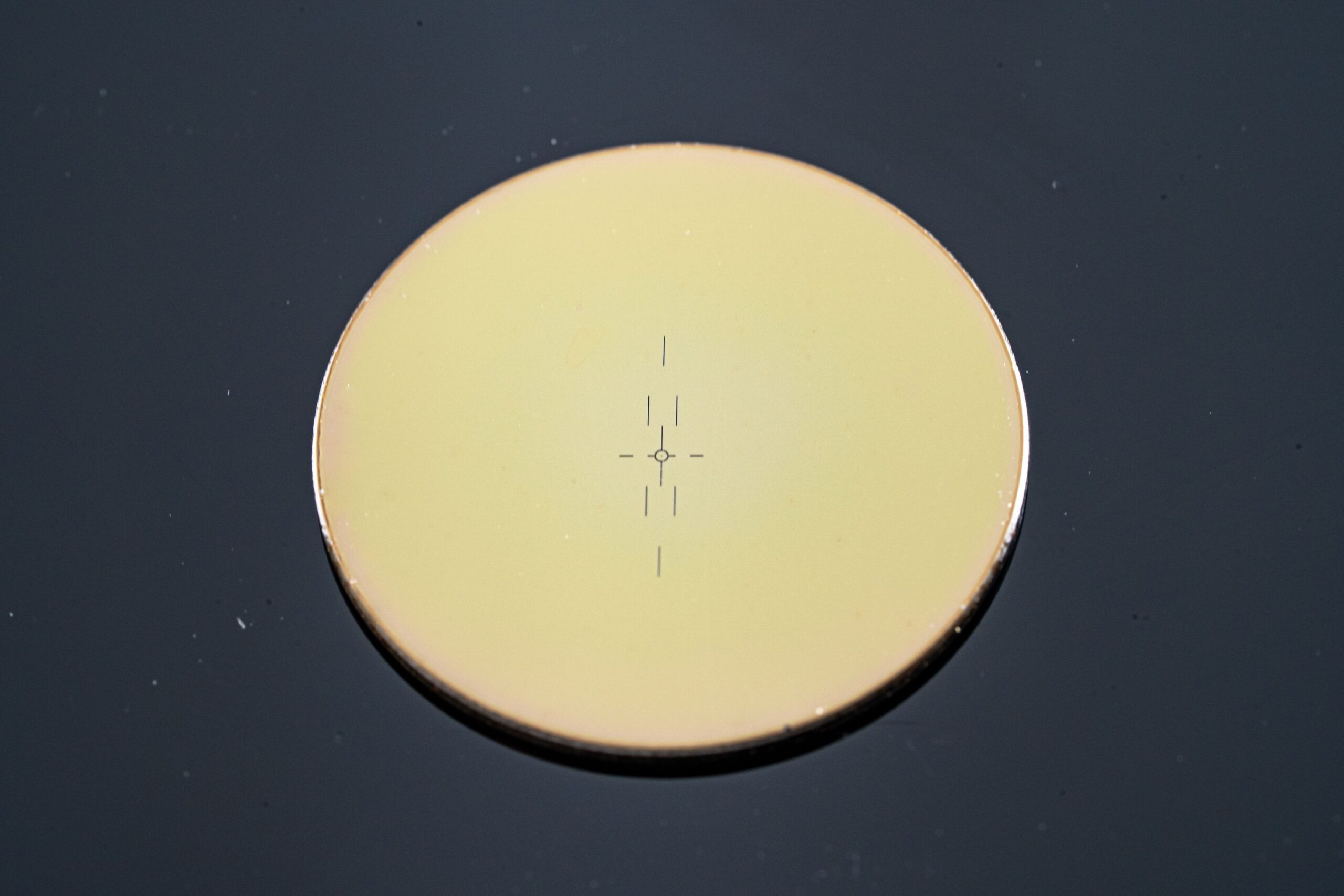

Salvo Technologies manufactures a wide variety of high-quality micro-patterned precision optics, including standard and custom reticle designs. We can offer the industry’s best precision reticles by utilizing our semiconductor patterning process. Our reticles are fabricated using multiple techniques: etch-and-fill, patterned dielectric, dichroic, and metal coatings. We supply our reticles to military and commercial applications, including direct view, projection, side illuminated, light field, and dark field varieties. In addition, reticles can be produced on prisms and other odd-shaped geometries to help designers make the most out of space requirements while maintaining performance. Our capabilities allow Salvo to add extra degrees of freedom to demanding designs previously not possible. All products meet environmental and physical specifications to military standard MIL-PRF-13830.

Our etch-and-fill reticles can be fabricated with line widths from .005mm-0.5mm. Reticles can be supplied with black, white, or red fill, and our photolithography techniques allow for superior line quality.

We also supply quality coated reticle products with metalized and/or dichroic films. Using Ion Assisted Deposition techniques allows us to provide components having excellent durability with superior temperature and humidity resistance. Our semiconductor patterning process will enable us to provide patterned, coated reticles with line widths down to 2µm with 1µm separation. Metal-coated products can also be supplied using the same photolithography techniques. These could be aluminum, anti-reflective chrome, or indium tin oxide coatings.

Any combination of these fabrication techniques can be used to meet your most demanding design criteria. Our semiconductor lithography process allows for large-volume reticle production, which means cost savings for our customers. By coating or etch-and-fill, we can fabricate products on large substrates and cut these into individual pieces, which is less time-consuming and leads to higher yields than manufacturing unique pieces. Having all the capabilities necessary to take raw stock to a finished product makes it easy to see how Salvo can offer the highest quality reticles in the industry.

A rifle scope’s interior operates similarly to a telescope. Light enters the scope body through a larger objective lens at the front, and an ocular lens illuminates the shooter’s eye at the rear. The ocular, magnification, focus and objective lenses are positioned between the eyepiece and the scope’s back end. Salvo Technologies manufactures complete riflescopes from the scope housing to the lens manufacturing and coating.

We have a broad range of coating capabilities to meet your needs, including coated, fully coated, multi-coated, and fully multi-coated.

A high-quality scope would have fully multi-coated lenses, which are the best option. The optical coating on a lens increases light transmission into the optics, minimizes light loss due to reflection, adds some scratch resistance, and decreases glare.

Custom Camera Lenses

Salvo Technologies now offers custom lens design in addition to lens assembly. From challenging designs for multiple wavelength sensors to a vast field of view in small packages, Salvo can create a solution that meets your application’s rigorous demands. Whether it is a new design or a redesign of an existing lens due to a senor change, Salvo’s engineers are eager to work with your customers to find a solution that meets their needs at a cost that will make the project successful. Applications range from space-qualified optics to medical and military-grade lenses.

At Salvo Technologies, we produce a high-quality extended-range line of Transmission Spheres (Tspheres). This line includes many standard F/# 633nm builds as well as custom F/# and custom wavelength transmission spheres available upon request. Transmission Spheres (Tspheres) are a necessary part of Fizeau interferometry and are used to measure the transmitted wavefront of optical systems and the reflected wavefront of optical surfaces.

As an example, when using an SLR camera, the camera body cannot take a picture without a camera lens attached. Similarly, an interferometer body cannot take a measurement without a Transmission sphere or Transmission flat. F/# is the ratio between focal length and Entrance Pupil Diameter where different F/#‘s are required to measure different radius optics. F/# can be simply thought of as the ratio between the Radius of Curvature and Visible aperture for reflected wavefront measurements. A “Faster” (smaller number) F/# can measure a larger area for a given Radius, but the focal length is shortened, limiting the Radius of Curvatures you can measure with it. Salvo Technologies’ line of transmission spheres offers several helpful advantages for interferometry, including:

- Proprietary Cody Kreischer extended range designs for measurement of longer convex Radius of Curvatures than comparable F/# Transmission Spheres

- Unique optical design to reduce the effects of lateral (tilt) retrace error

- more catalog standard F/#‘s than found from other sources, which fill in the gaps in metrology.

The key to the accuracy of a Transmission sphere is the final surface of the assembly, known as the reference surface. When light from the interferometer passes through the reference, the resulting wavefront interferes with the surface(s) under test. In general, the reference surface is assumed to be perfect, and all the interference that is measured by the interferometer is assumed to be from the part under test. Salvo Technologies high precision, pitch polished reference surfaces for smooth, low irregularity wavefronts. This level of optical workmanship allows us to offer all our T-Spheres (including our F/0.56) at λ/20 quality (at λ = 632.8nm) and most at λ/40 level.

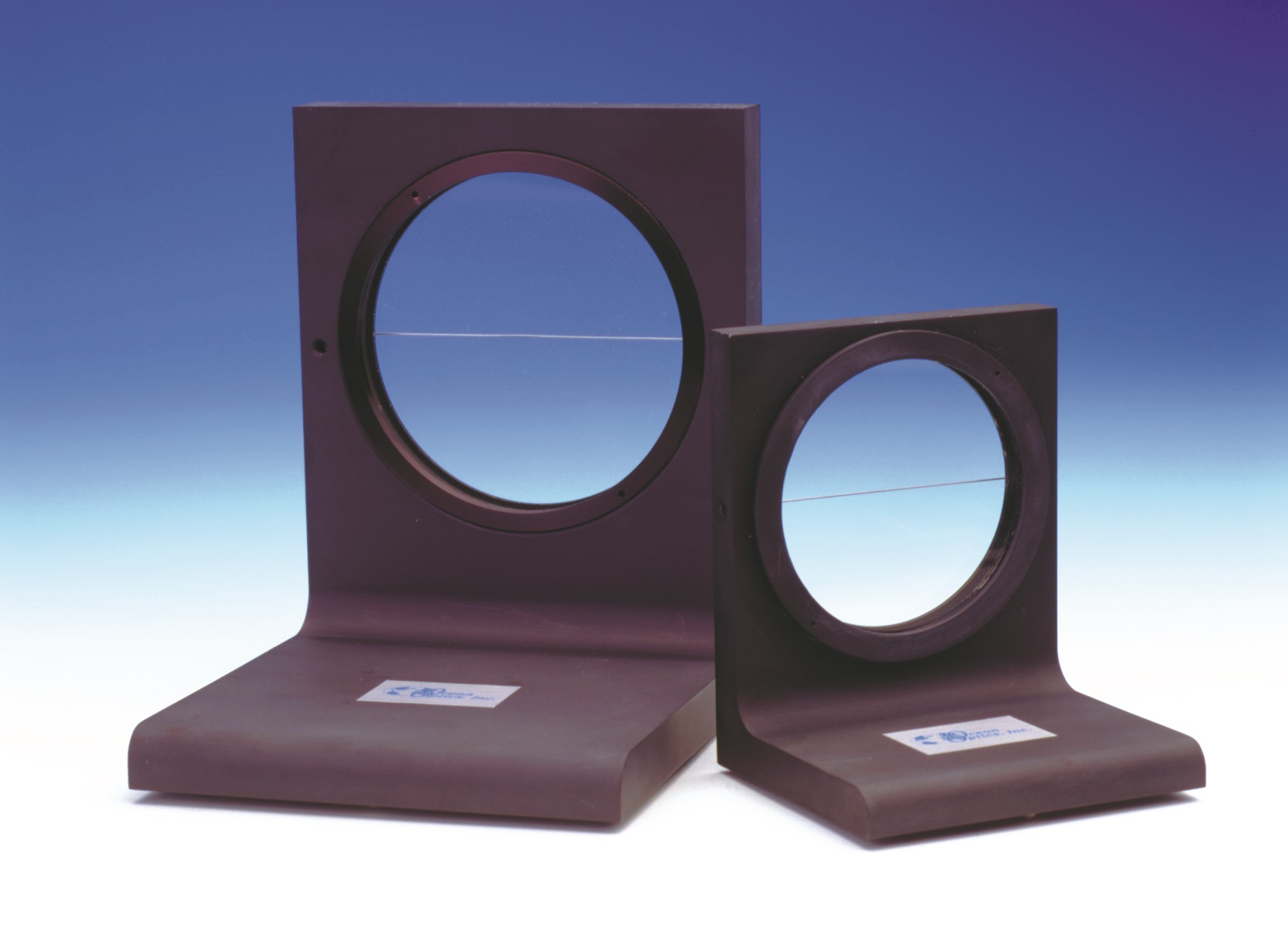

Collimation Tester – CT/Shereplate

Salvo Technologies shear-plate collimation testers are wedged, high-quality optical flat aligned for the specific λ wavelengths of interest to be utilized in the testing of collimation of a wavefront on optical benches, optical trains, and systems. The lateral-shearing interference patterns produced on this shear plate can be used to examine and adjust the collimation of laser light and other emission sources. The testers can also measure wavefront curvature and quantify divergence/convergence magnitude.

Usable in the 350-2500nm wavelength range, each shear plate collimation tester consists of a wedged, high-quality optical flat aligned for the specific wavelengths of interest to be tested for collimation wavefront housed in a heavy-duty anodized aluminum frame. Testers are available with apertures ranging from 10 to 200 millimeters in diameter.

Aperture Sizes Available: 50mm, 75mm, 100mm, 125mm, 150mm, 200mm, 250mm