Motorized Zoom Lenses

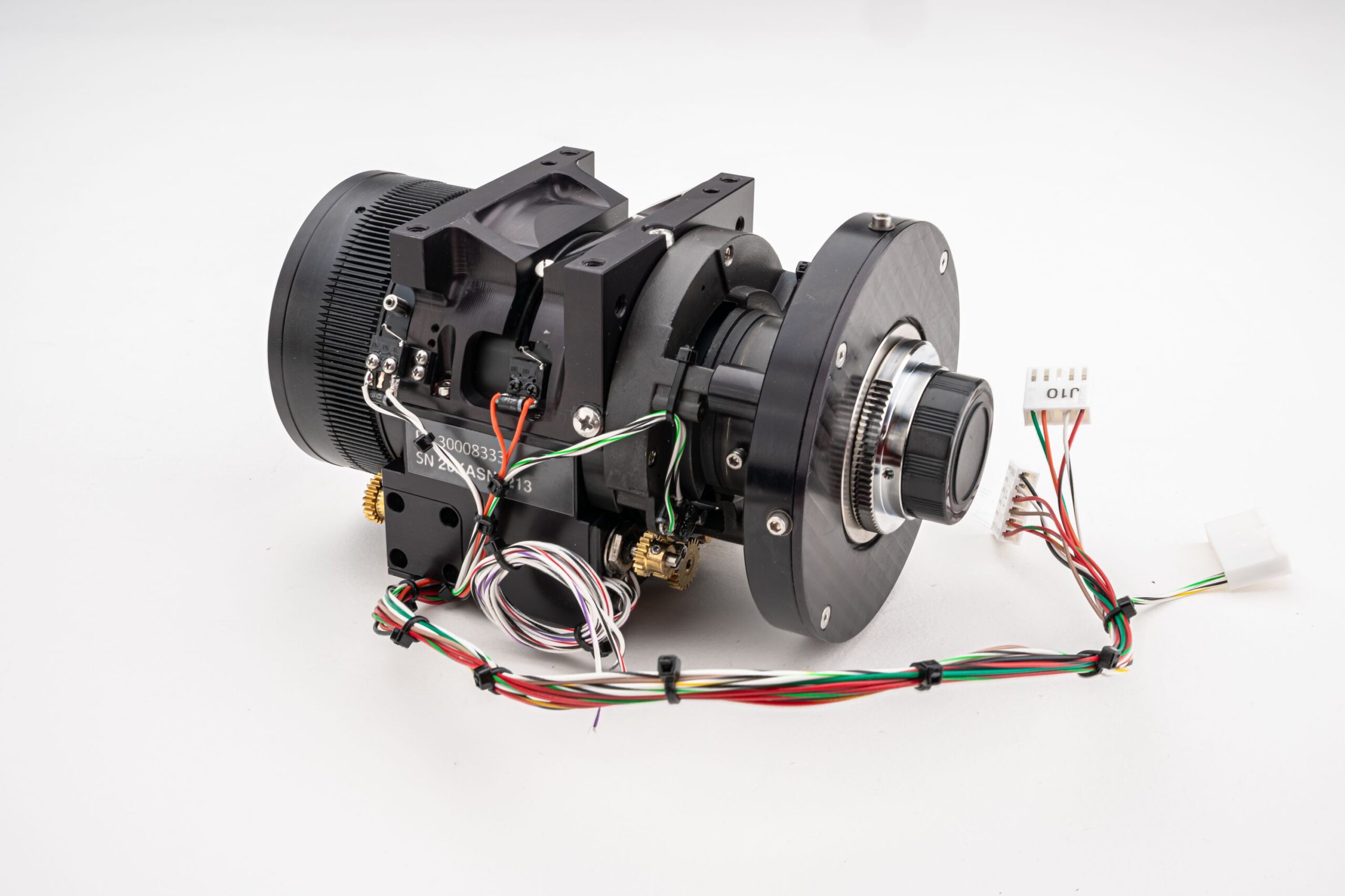

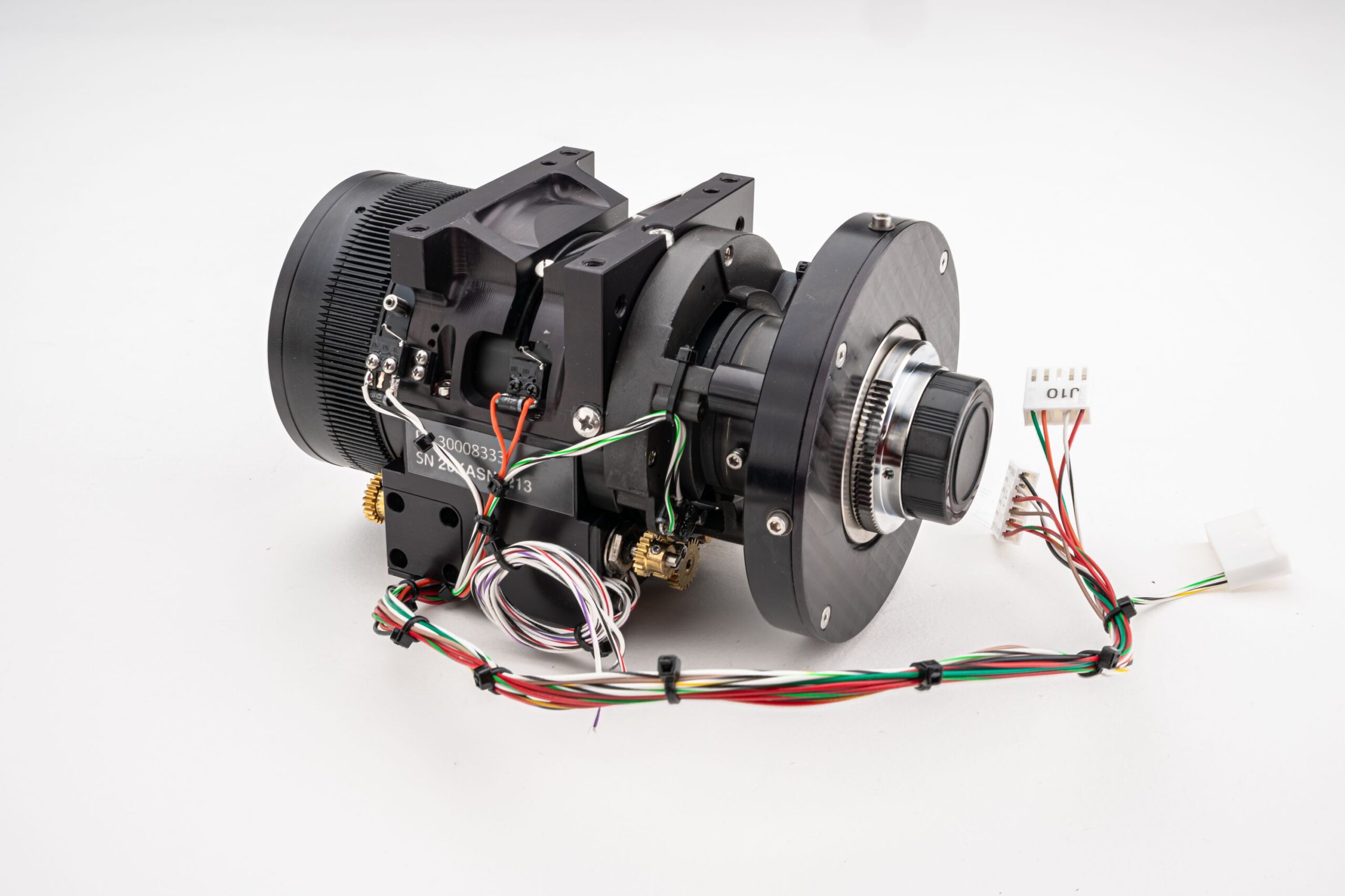

Salvo Technologies Motorized Zoom Lenses have been designed and built to provide the utmost performance, reliability, and durability. Designed to meet the basic requirements of short, medium, or long-range systems, our broad line of zoom lenses will satisfy various applications. In addition to continuous zoom lenses, we also offer modular designs, custom brackets, extreme temperature gear motors, and unique electronic/electrical interfaces and enhancements that provide a wide range of options to satisfy many different requirements.

Our reputation for providing superb products, including a high degree of optical performance and the inherent design qualities meant to withstand the harshest of environments, is world-renowned. We consider that our lenses will be subjected to severe shock, whether mechanical or environmental; therefore, throughout the design stage, we apply debilitating vibration and extreme temperatures, making our lenses inherently rugged.

Salvo Technologies understands standard products will rarely satisfy the needs of a particular requirement. However, with a high degree of insight derived from extensive experience and a large portfolio of interchangeable design approaches, we can customize a standard lens to meet unique requirements. Options meant to enhance standard products by transforming them to meet specific needs include our DIS-III Digital Lens Control System, the BCD for improved boresight retention, the ZHS-II Instrument Heat System, wide temperature range gearmotors, and optical encoders, to name a few.

Most all Graflex zoom lenses are designed to match an established standard specification and to meet minimum environmental performance. Further, most all lenses may be customized to a required specification. Therefore, don’t hesitate to contact the factory for the exact standard associated with each lens and available customizations.

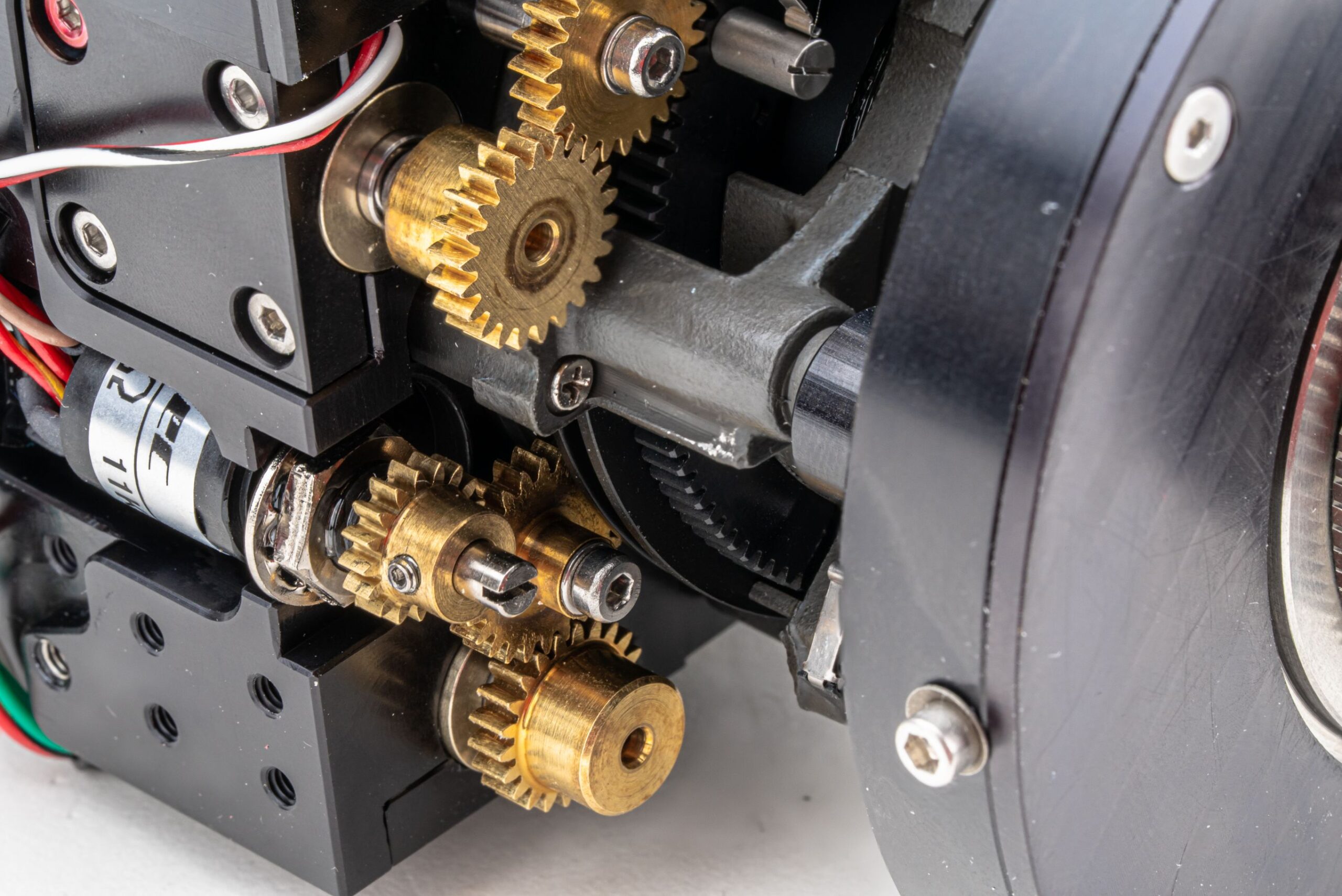

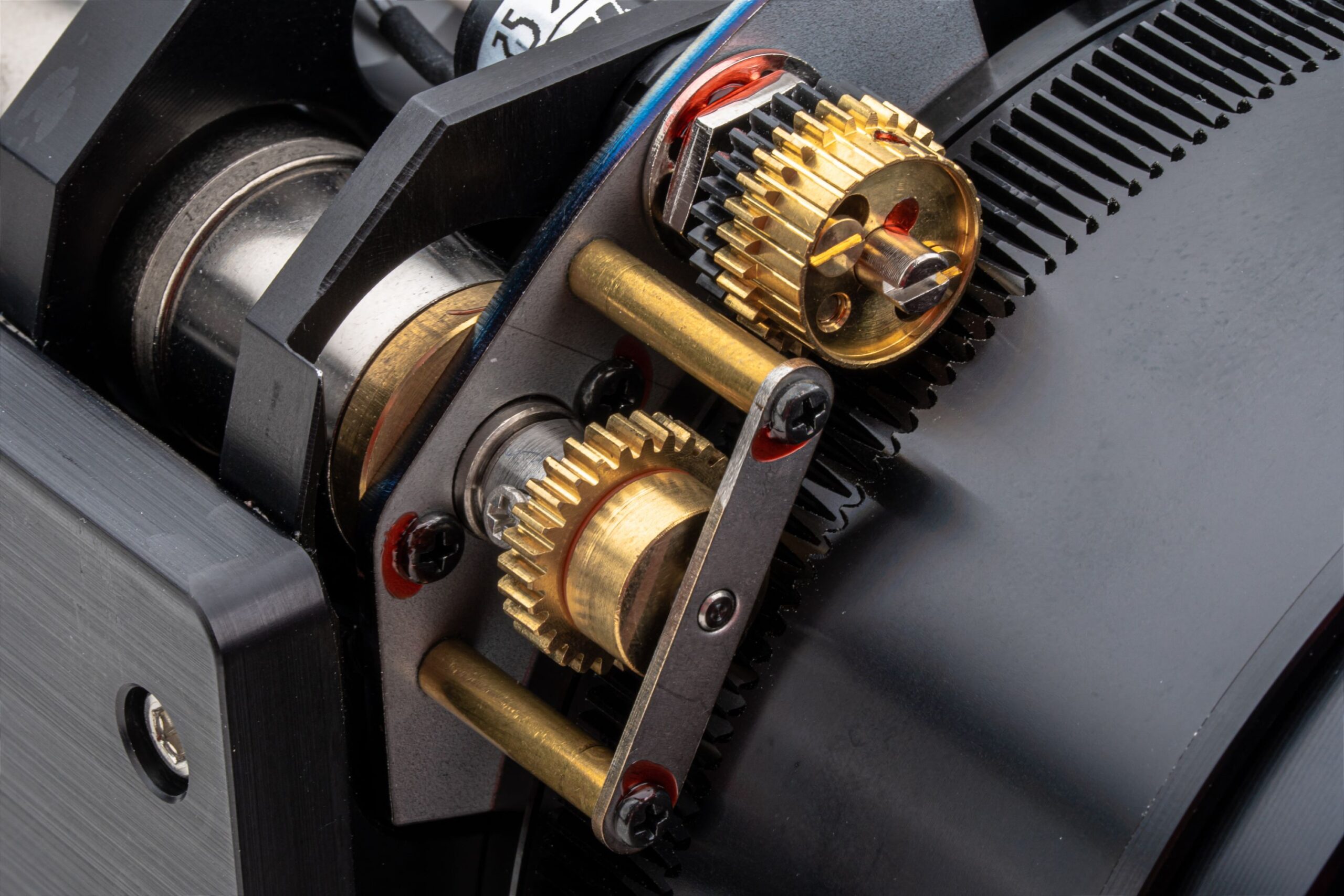

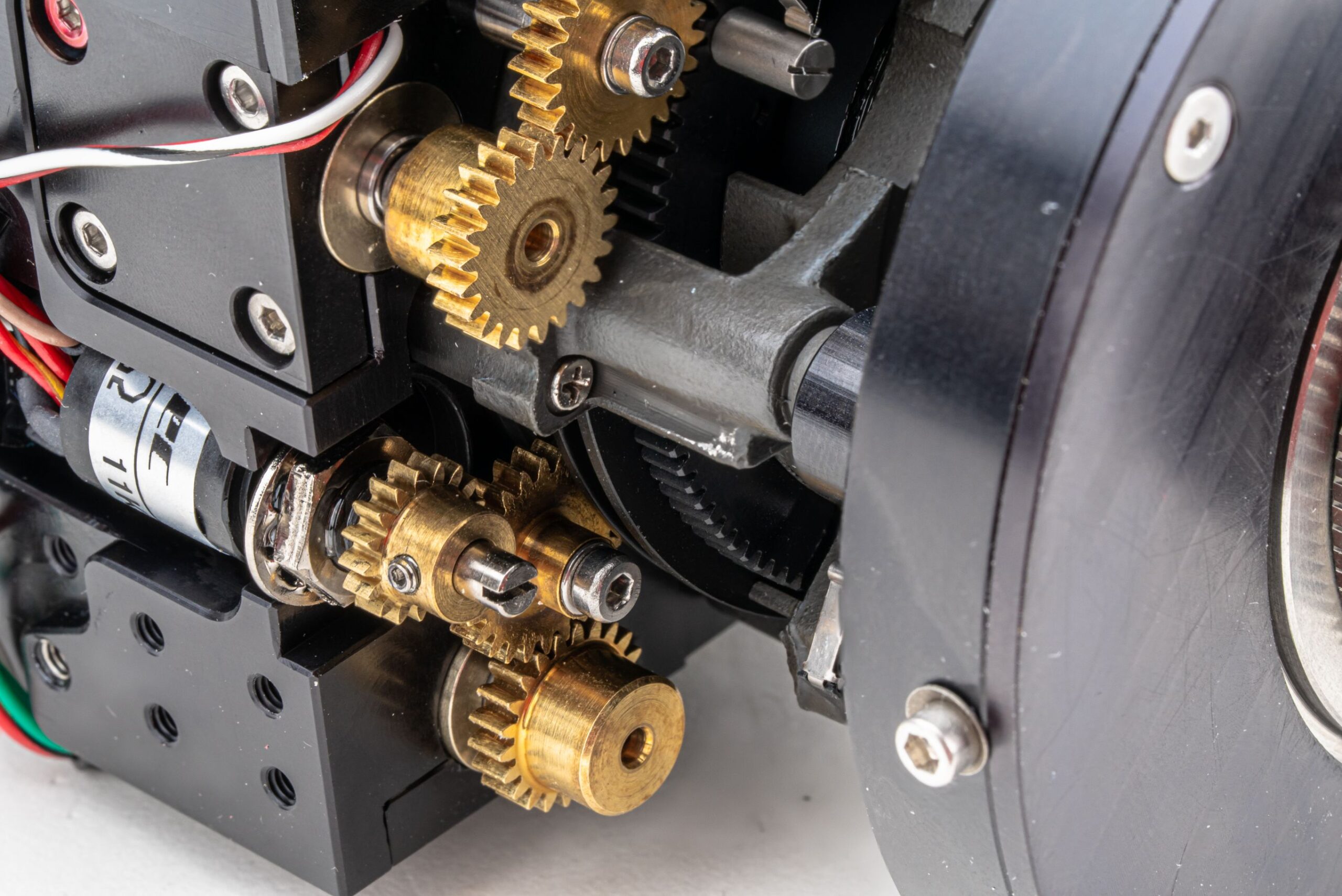

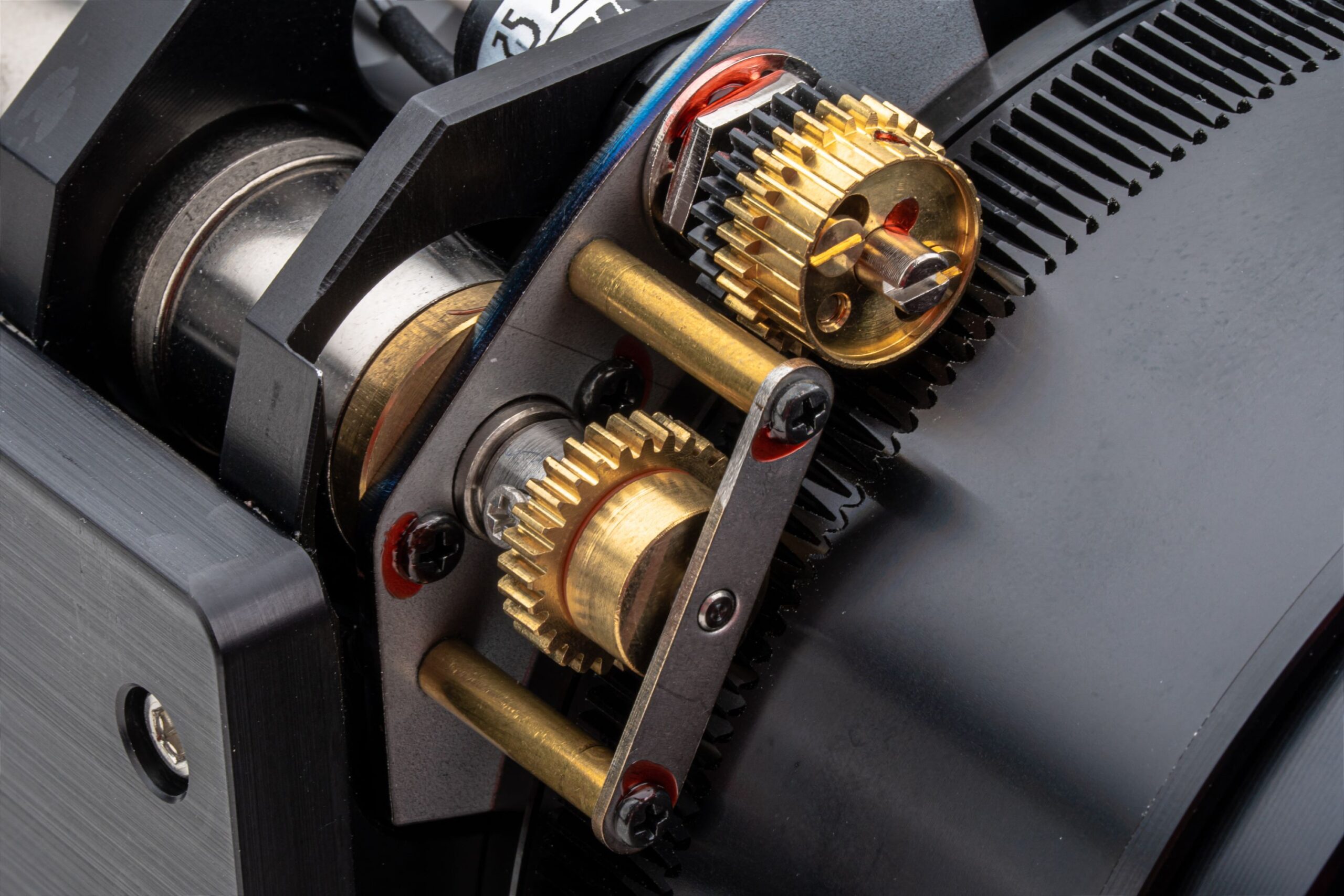

- All metal gears

- Superb transmittance

- Excellent boresight retention

- Excellent thermal stability (Optically & mechanically)

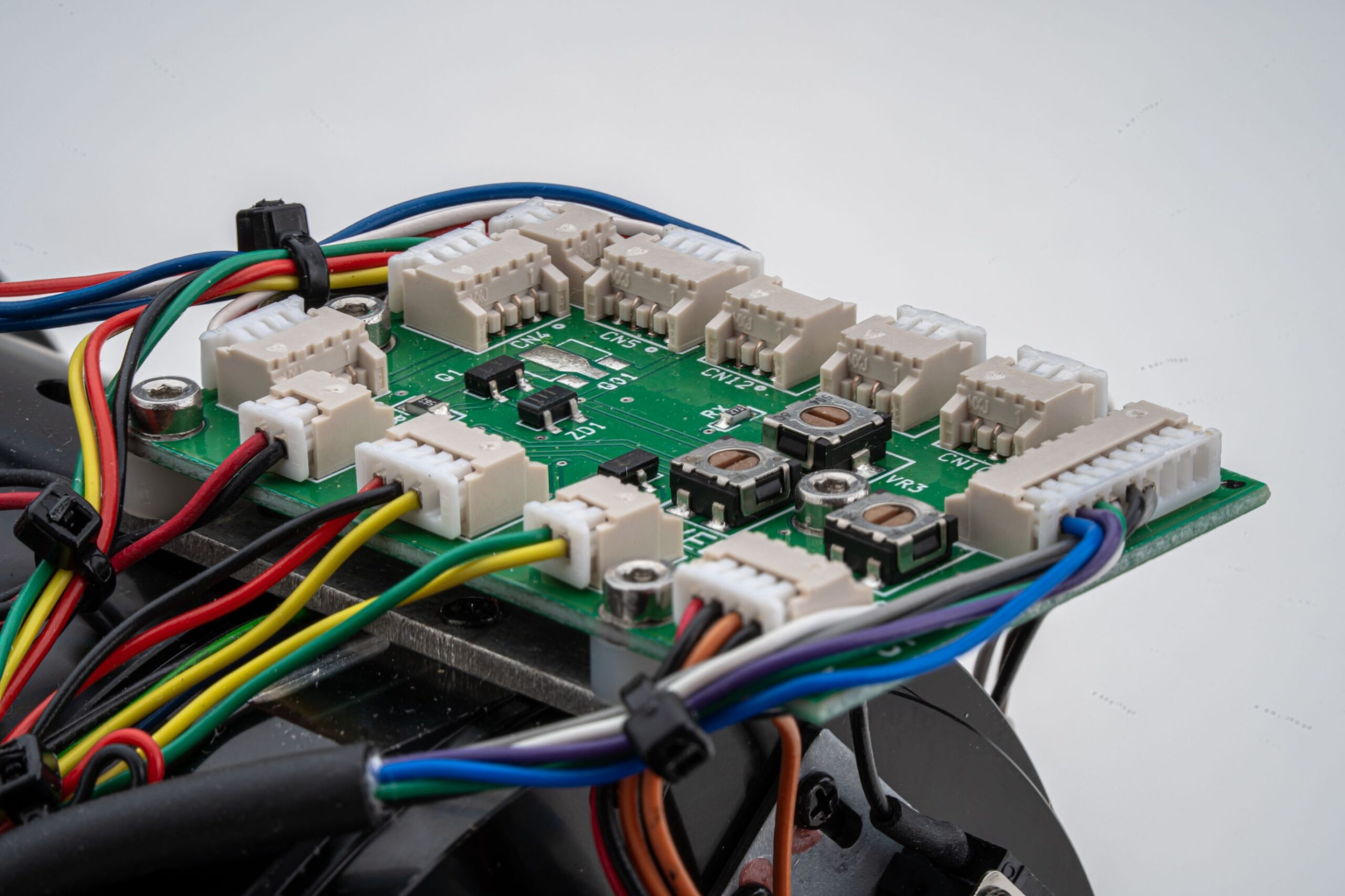

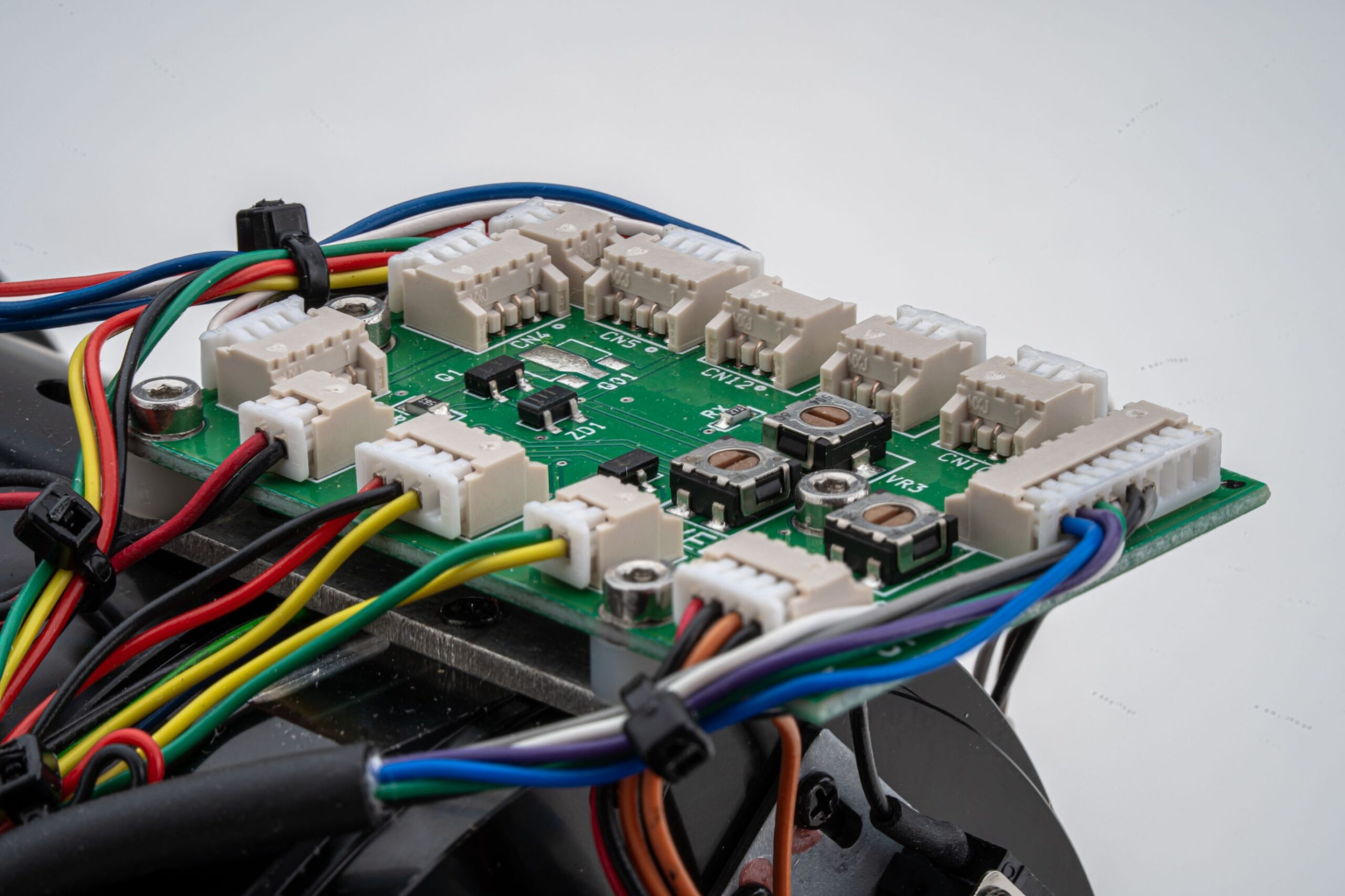

| Iris: | 8-16Vdc @ 30mA, 0.4V to 1.0V (Peak to Peak) |

|---|---|

| Zoom/Focus: | 6-12Vdc @ 60mA |

| AI PCB: | 3.0Vdc @ 21mA |

| Position: | Potentiometers at Zoom & Focus |

| Iris Control: | Auto |

| Control: | Analog |

- Operating Temperature: The zoom lens will operate after having been exposed and thermally stabilized to any temperature within the range of -30°C to +70°C

- Storage/Transit Temperature: The zoom lens will not be damaged after having been exposed and thermally stabilized to any temperature within the range of -40°C to +75°C

- Shock: The zoom lens will not be damaged while subjected to three shocks of 7.5 g for 11msec saw tooth on each axis, in both directions (18 pulses total)

- Vibration: The zoom lens will operate and not suffer damage when subjected to axial vibration (not angular) or 0.1gRMS within the frequency range of 10-150 Hz

Note:

- Our approach relative to surviving severe environments is to work with our customers to “overcome” any failures which may occur through the testing phase of a lens; it is the responsibility of the customer to environmental test the lens; Salvo will make changes and recommendations based on any failures. We will not warranty lenses for damage resulting from shock, vibration, or other severe environmental inputs.

- Published specifications may or may not apply to a specific lens. Please contact the factory for specifications as they apply to a particular lens.

Zoom Lens Upgrades & Options

Most Zoom Lenses are built according to a specific customer standard. Variations include electronic, control methods, electrical interface, ruggedization, optical, and bracketry/mechanical interface. With a long portfolio of upgrades, customizations are typically applied with no NRE expense.

| Optical (MTF) Testing: | Via our state of the art MTF system, Graflex is also able to provide complete lens analysis services including MTF (1D & 2D), LTF, EFL, flange FL, BFL, focus deviation, boresight deviation & retention, astigmatism, and depth of focus. Lens capability through approximately 2030mm and 8″ free aperture. |

|---|---|

| BCD Align Device: | The Graflex BCD (Boresight Compensation Device) is a mechanical device that greatly improves the inherent boresight retention of most any zoom lens. |

| DIS-III Controller: | The Graflex DIS-III controller includes a PCB and GUI and may be applied to most any zoom lens no matter the manufacturer. The system not only allows for serial interface via RS-232, RS-422, and RS-485, but also Ethernet. The DIS-III is also VISCA and PELCO compatible. |

| CFE Lens Enclosures: | The Graflex family of CFE Carbon Fiber Enclosures are not really an option but a product within itself. At a fraction of the density of aluminum, carbon fiber is a clear choice where extreme strength and low weight are desired characteristics. Although we manufacture standard sizes, the size/shape possibilities are endless. |

| ZHS-II Heat System: | The ZHS-II applies concentrated heat direct to the zoom lens, or any other device, via small heater pads. The ZHS-II system includes heater elements, thermostat, and is fully programable via a separate controller. |

| Mechanical Interface | Beyond a wide range of standards, Graflex will build custom interface brackets to meet any requirement. From the simple addition of alignment pins to multi-axis tilt and lock brackets we can, and have, done it all. |

| Gear Motors: | Outside of the standard 12Vdc in most lenses, we also offer 6Vdc and 9Vdc motors, non-standard gearbox ratios, wide (low to high) temperature grease, and encoders. |

| Electrical/Electronic: | In most lenses, we offer closed and open-loop systems, customer specified connectors, and encoders. |

| Ruggedization: | We possess the knowledge and experience of modifying zoom lenses for the most severe environments. Our projects include modifications to survive shock up to 75 g’s, temperatures as low as- 45° celcius, and severe functional vibration (and the removal of resultant video distortion). |